Standard Features and Benefits

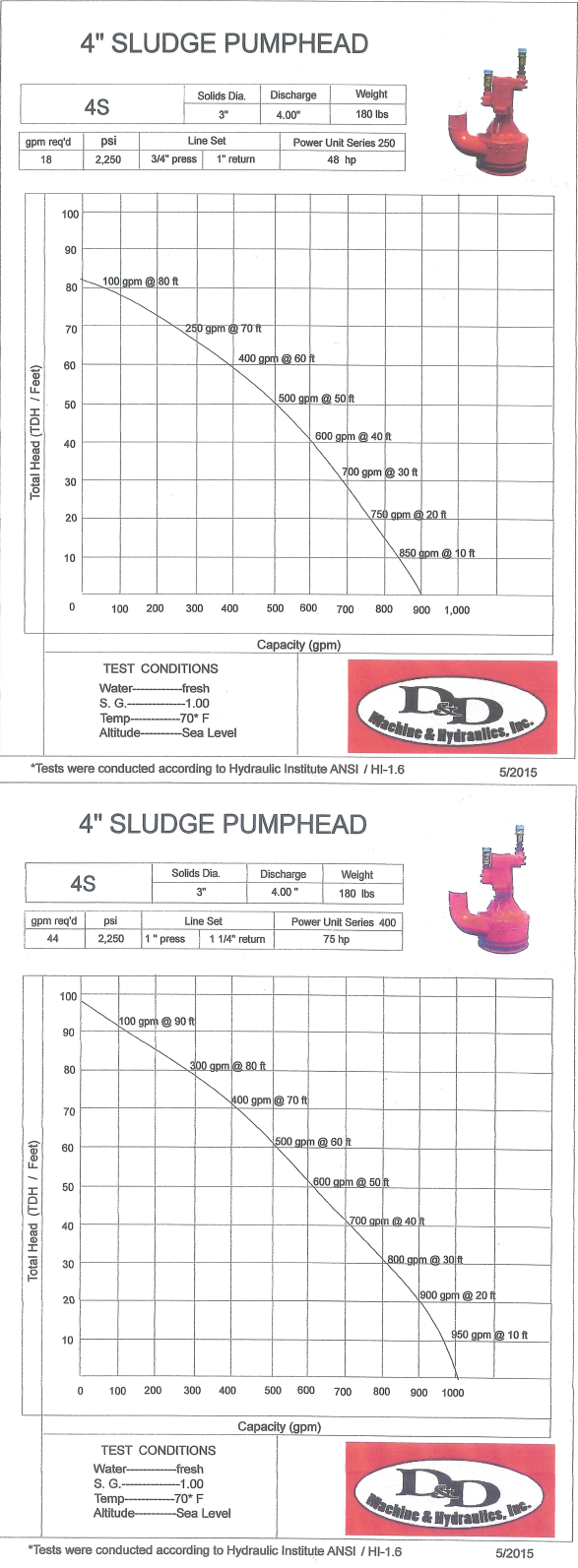

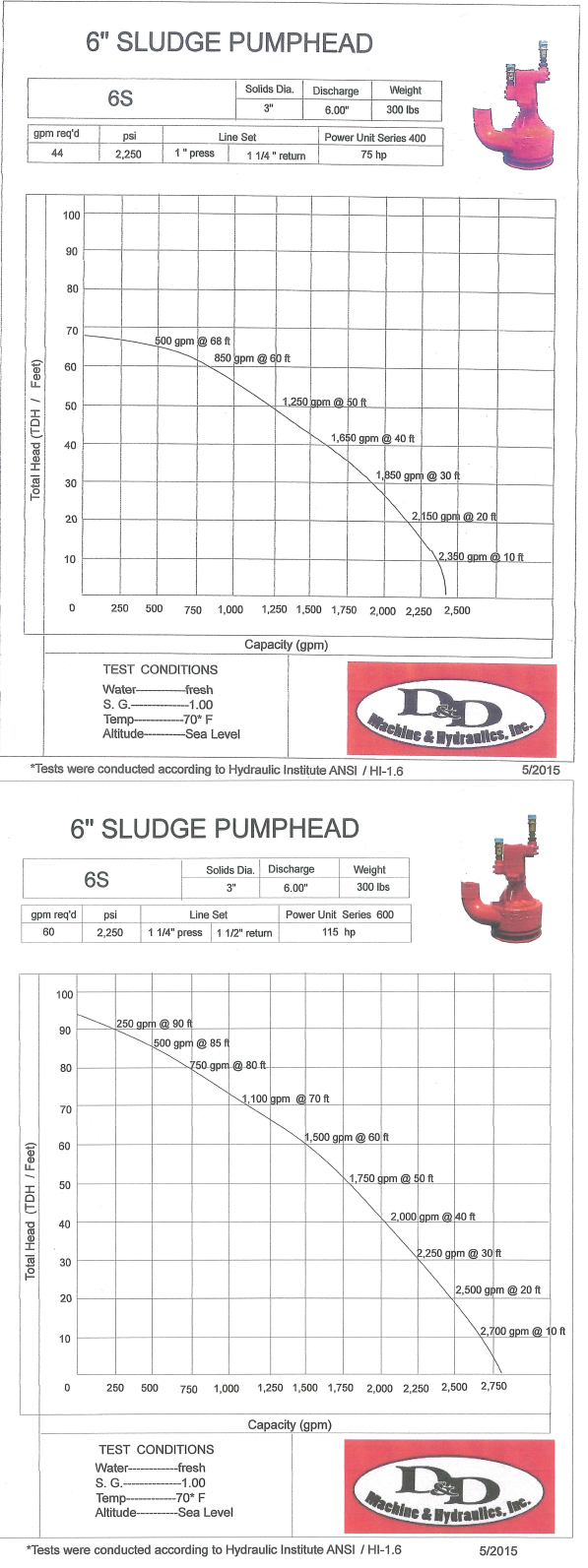

Due to the versatility of the sludge pump, many users prefer it even though the horse power per gallon is greater than the Trash Pump. The additional power requirements and somewhat reduced volume of the Sludge Pump, is more than offset by the extended life of the unit in certain abrasive pumping requirements. The Sludge Pump is ideal for pumping mud, sewage, silt, and other viscous materials, that cannot be pumped with conventional lift pumps. Sludge pumps are available in 4″ and 6″ diameter discharge.

Submersible Open Type Sludge Pump

The submersible Sludge Pump has all the advantages of the open type trash pump, but due to the impeller design, it will pump extremely high percent solid content liquids. The Sludge Pump impeller is of the tapered vane design. It permits the water to enter the bottom eye of the housing and accelerates the liquid in a radial fashion out the concentric discharge usually in one revolution. With impeller types of this configuration, large solids can be passed without clogging and relatively little impeller wear occurs. Normally, greater horsepower per gallon is required for sludge type pumps.

- Special hydraulic motor, provides bearing lubrication.

- Flow capabilities: 900 gpm ‐ 2,300 gpm.

- Cast steel bearing tube, oil bath bearing lubrication.

- 304 stainless steel pump shaft, longer pump life.

- Two sets of ball bearings, no wear due to side load.

- Fabricated iron Volute and impeller.

- Special energy transfer impeller, can pump high solid content material with low impeller wear.

- Lifting bale, easy to move.

- Inlet screen, keeps out over-sized objects.

- Spin on hydraulic connections, fast setup.