Standard Features and Benefits

The D&D Slurry Digester Pump is specifically designed for pumping sewage, silt, and other viscous material that cannot be pumped with conventional lift pumps. In addition to a tapered impeller, the D&D Digester Pump is equipped with an external hard faced “Agitator Impeller”. This dual design allows the pump to breakup solids with no disruption in the pump output flow. No need to start and stop the pump. No added valves and hoses to contend with. The digger is completely removable, allowing the operator to use the pumphead as strictly a sludge unit. The bottom cage remains on the pumphead.

Submersible Digester Pumps

The Digester Pump has all the advantages of our Sludge Pump; but because of the design of the blade angle on the impeller, it provides a cutting action as well as pumping an extremely high percentage of solid content liquids. The Digester Pump impeller is of the tapered vane design. It permits the water to enter the bottom eye of the housing, past the “Agitator Impeller”, and accelerates the liquid in a radial fashion out of the concentric discharge, usually in one revolution.

With impeller types of this configuration and steel blade design, large solids can be passed without clogging, and relatively little impeller wear occurs. Combined with the D&D pumphead, the D&D submersible digester pump becomes a unit with pumping abilities unparalleled in the industry.

- Special modified hydraulic motor, provides bearing lubrication.

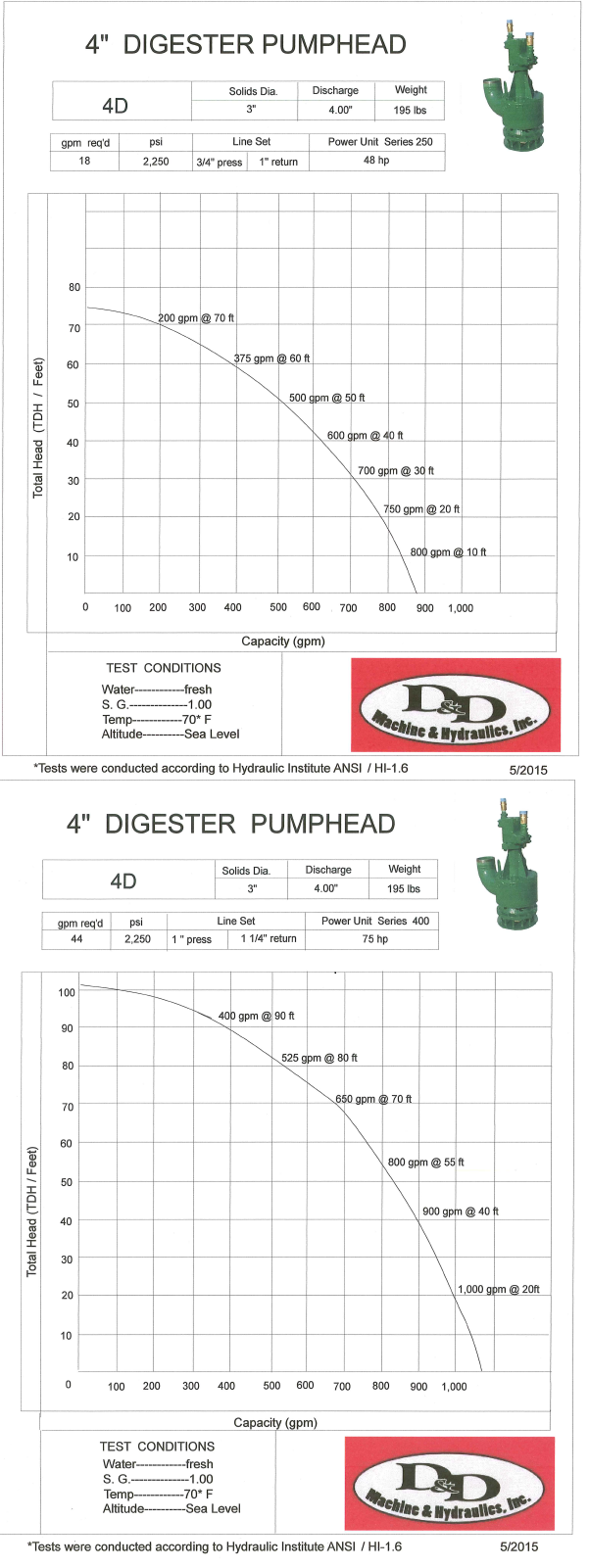

- Flow capabilities: 900 gpm ‐ 2,300 gpm.

- Steel bearing tube, oil bath bearing lubrication.

- 304 stainless steel pump shaft, for longer pump life.

- Two sets of ball bearings, no wear due to side load.

- Corten Steel Volute and impeller, uniform performance (Hardened impeller available).

- Special tapered impeller with cutting edge.

- “Agitator” impeller with cutting effect.

- Lifting bale, easy to move. Inlet screen, keeps out oversized objects.

- Spins on hydraulic connections, fast setup.